Apparent Quality Problems Due to Poor Workmanship or Manufacturing Skills The common apparent quality problems that fall into this category are:

- a) Apparent garment problems due to patterns. Generally speaking, if a sample of exercise outfit for ladies is approved, the patterns for medium size of garments are defined. If a whole lot of finished garments do not conform to the measurements specified, it is necessary to check the Incorrect grading rules adopted may be a prime cause. It is advisable to make good workout clothes samples for both the largest and the smallest sizes after grading. Subsequently, measurements for all locations could be checked according to the size chart and, furthermore, the athleisure clothes appearance should be examined to ensure that grading on the curved parts of a garment say armholes and necklines, are perfect. If only a few of the garments do not conform to the specified measurements, this may be due to faults in the sewing operations, possibly by the operator who did not strictly follow the seam allowances indicated by notches.

- b) Apparent garment problems due to marker making, spreading, and cutting. If the check or stripe patterns on activewear apparel pieces are not correctly matched or if the drapes of the left side and right side of a garment are not satisfactorily balanced, there could be something wrong with the marker. The former is due to inconsiderate marker making and the latter may be due to poor alignment of the grain lines of garment pieces. Uneven and excessive tension applied during fabric spreading may also cause relaxation shrinkage which could affect garment measurements. Poor cutting skills could cause cut edges not to be perpendicular to the cutting table and this, no doubt, could also affect the size of the cut parts and hence garment measurements.

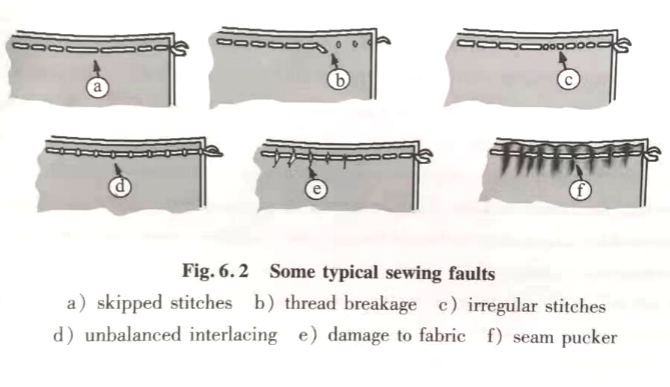

- c) Apparent garment problems due to sewing. There are several kinds of common faults such as skipped stitches, thread breakages, irregular stitches, damage to fabrics, and seam puckering, which would prevent a garment from being a best workout outfits.

Sewing faults may arise from the improper setting of the machine parts.

For example, improperly setting the thread tension or incorrectly selecting or setting the needle could cause thread breakages, and insufficient pressure on the presser foot could cause irregular stitches.

Sewing faults may also arise from defective machine parts. Burrs on the needle or on the throat plate could cause thread breakages. Excessive sewing thread tensions or structural jamming may cause seam pucker. Furthermore, poor skill by the operator may lead to sewing faults including seam pucker. It should be noted that some faults might be attributed to the material being sewn. Seam pucker could sometimes fall into this category and one way to solve the problem may be to attach a strip of interlining as a stay tape along the seam line to be joined to reinforce it and increase its bending rigidity.

There are other apparent garment quality problems that may be attributed to the poor sewing skills of the operators. These include seam lines such as top stitching not being even, the left and right of a garment not being balanced, sleeves veering towards the front or back, the top collar being set too tight, etc. Some of these problems could be remedied by skillful ironing operations but others may not. Consequently, new workers should be well-trained before being allowed onto the production lines.

- d) Apparent garment problems due to ironing. Garments are usually ironed between sewing operations ( called under pressing) or on completion of sewing operations ( called toppressing). Poor ironing skills or incorrect setting of the ironing temperature would leave ironing marks on the garment. Glazed or yellowish spots appearing on a garment after ironing tend to be the most common ironing faults. Insufficient pressing or over-pressing may also occur because the ironing time, temperature, pressure, and the steam applied wholly depend on the operator's experience in hand ironing. Therefore if it is possible, it is better not to use an iron for the final garment pressing because the final quality of the garments will depend on the skill of the ironing

It must be borne in mind that the cause of the apparent problems might often be complex. For example, a wrinkle in a certain part of a garment may be caused by differential shrinkage between the shell and lining, or by poor workmanship, etc. Consequently, it is essential in the early stages of garment manufacture to find the exact cause and then devise appropriate remedies. In the context of garment quality, remember that prevention is better than a cure.