The sustainable clothing does not only refer to the use of waste materials with juicers on the show, or the design of degradable paper clothing. Its general urgency does not stand in one link, nor is it limited to one aspect. It is not only a "highlight" in pursuit of low carbon emissions, but runs through the use of materials, design methods, production processes, operation management, and wearing functions. And then to convenient and low-consumption care, waste recycling and other aspects.

Each point must meet the requirements of ecological and environmental protection, and reduce the load on the environment as much as possible. In summary, "green and pollution-free, emission reduction, energy saving, comfort and safety, and recycling" are the most omni-directional, multi-faceted, and most essential concept of sustainable clothing.

From unsustainable manufacturing methods to plastic waste flooding the ocean, the fashion industry is the world's second largest environmental pollution producer after the petrochemical industry.

The textile industry emits 1.2 billion tons of greenhouse gases each year, accounting for 10% of the total global emissions. Textile fiber, yarn, and fabric manufacturers are the main emitters of greenhouse gases in the fashion industry. According to statistics, 34% of the microplastics found in the ocean come from the textile and clothing industries, most of which are made of polyester, polyethylene, acrylic and elastic fibers.

Fitfever Solutions

REPREVE®

ECONYL®

LYCRA ®

ORGANIC COTTON

TENCEL®

SEA WOOL®

SORONA®

NATURAL BUTTONS

GEM BUTTONS

Color is a key element of fashion fashion, but industrial printing and dyeing needs to consume a lot of chemical dyes, auxiliaries and water resources, resulting in the emission and residue of harmful substances, which affects the ecological environment and the health of clothing.

OEKO-TEX 100 mill

OEKO-TEX Standard 100 is now the most widely used textile eco-mark. The OEKO-TEX Standard 100 stipulates a standard based on the latest scientific knowledge to set limits on the content of harmful substances in yarns, fibers and various textiles. The test includes PH value, formaldehyde, extractable heavy metals, nickel, pesticides/herbicides, chlorinated phenols, cleavable aromatic amine dyes, allergenic dyes, organic chlorinated dyestuffs, organic tin compounds (TBT/DBT), PVC plasticizer, color fastness, organic volatile gas, smell.

Digital print

Compared with the traditional printing process, digital printing shortens the production process and time by reducing the consumption of screen-making labor, space and printing screen. Meanwhile it greatly reduces the consumption of dyes and dyeing waste water. Moreover, the pattern design is not restricted by the printing process, and is very suitable for the needs of small batches, multiple changes, and fast fashion. In recent years, digital printing has also become one of the high-profile focal points on the runway.

In 1998, researchers found a plastic bag in the Mariana Trench, which was 10,898 meters deep. This was one of 3,000+ deep-sea garbage fragments discovered in the past 30 years. In 2017, JAMSTEC's global ocean data center opened the deep-sea garbage database to the public. Among the deep-sea garbage debris found so far, more than one-third are large pieces of plastic, and 89% are disposable product waste.

At a depth of 6,000 meters, more than half of the garbage debris is plastic, and almost all are disposable items. Diving in the deep ocean, plastic waste can exist for thousands of years. Reducing the generation of plastic waste is the only way to solve the problem of deep-sea plastic pollution.

Biodegradable Garment Bag

PBAT+PLA raw materials, NO PE, environmentally friendly ink printing. Passed American BPI certification and German DIN CERTCO certification. Tested under European EN 13432, American ASTM D 6400 and Australian AS4736 standard conditions.

Biodegradable Mailer

Imported PLA raw materials, NO PE. It’s 100% compostable being buried in the ground through microbial degradation. Therefore reduce the negative impact on the environment. It completely degraded within 90 days in industrial compost. And in the natural environment it is completely degraded within 2-4 years. Certified by American BPI, Germany DIN CERTCO.

Accurate Production

The concept of sustainable development is embodied in a series of processes of clothing production, which is to reduce the discharge of noise, waste water. We always strengthen scientific management in production, making the best use of materials, and guide green production. We aim to reduce blind production and truly achieve less and more precision.

Digital Marketing

In the process of clothing sales, publicity for clothing products is a must. Publicity spread mainly through various online media such as the web, platform, social media, very limited to newspapers and magazines. By doing so, we automatically save papers and heavy transportation energy waste.

Fast fashion companies continue to shorten the production cycle and increase the frequency of new product launches, posing a huge threat to the environment. Every year, more than 80 billion pieces of clothes are produced. At the same time, 13 million tons of clothes are discarded every year. Behind the high prosperity and development of the fashion industry is the high consumption of resources.

Fast fashion companies continue to shorten the production cycle and increase the frequency of new product launches, posing a huge threat to the environment. Every year, more than 80 billion pieces of clothes are produced. At the same time, 13 million tons of clothes are discarded every year. Behind the high prosperity and development of the fashion industry is the high consumption of resources.

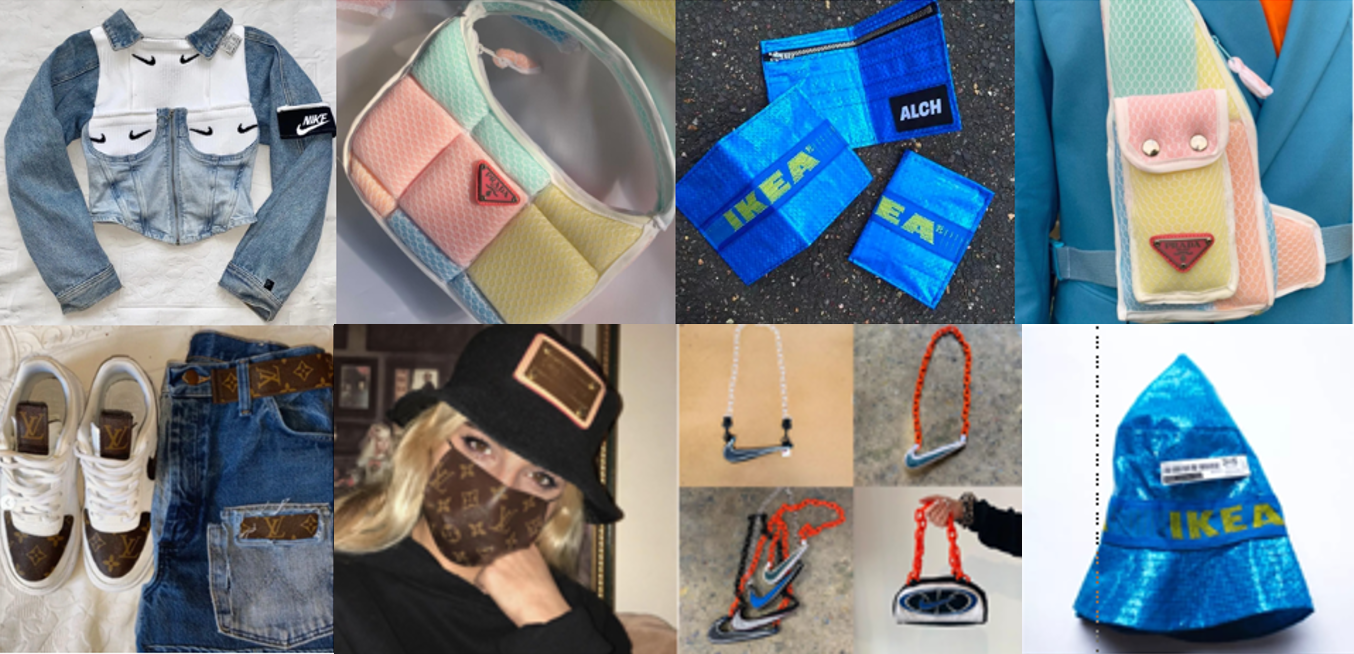

The design concept of semi-finished products can transform consumers' creativity, preferences and even personal memories into clothing design elements, so that consumers can be satisfied, and it is easier to form attachments to clothing. The detachable design concept allows products to be quickly disassembled and reorganized into modules, which is also one of the practical strategies for sustainable clothing design.

Emotion is the attitude and experience that people produce when they meet their own needs with objective things. The emotional design value of sustainable clothing is directly related to the service life of clothing.

Emotional lasting design is based on an in-depth understanding of individual consumer needs and values, and its purpose is to design products that are meaningful to users for a long time, so that they are not easily discarded.

At present, open source fashion design has become a trend, and fashion designers can still promote their design skills, but the final design results are realized by end users, turning consumers into active manufacturers, deepening the emotional connection of clothing, and extending the The life cycle of clothing is of great significance.

Everything you need to create a sustainable clothing line

Address

Phone

0086-57186229186