- STEP 1. Techpack Drawing Analyze

Wholesale gym clothing suppliers look at the style drawings used in production, which should include renderings of the garment, along with content such as the variety, color, and pattern of the fabric. When designing styles, factory personnel also need to consider the cost of custom made clothing, such as the cost of fabric accessories, processing costs, transportation costs, and production cycle estimates.

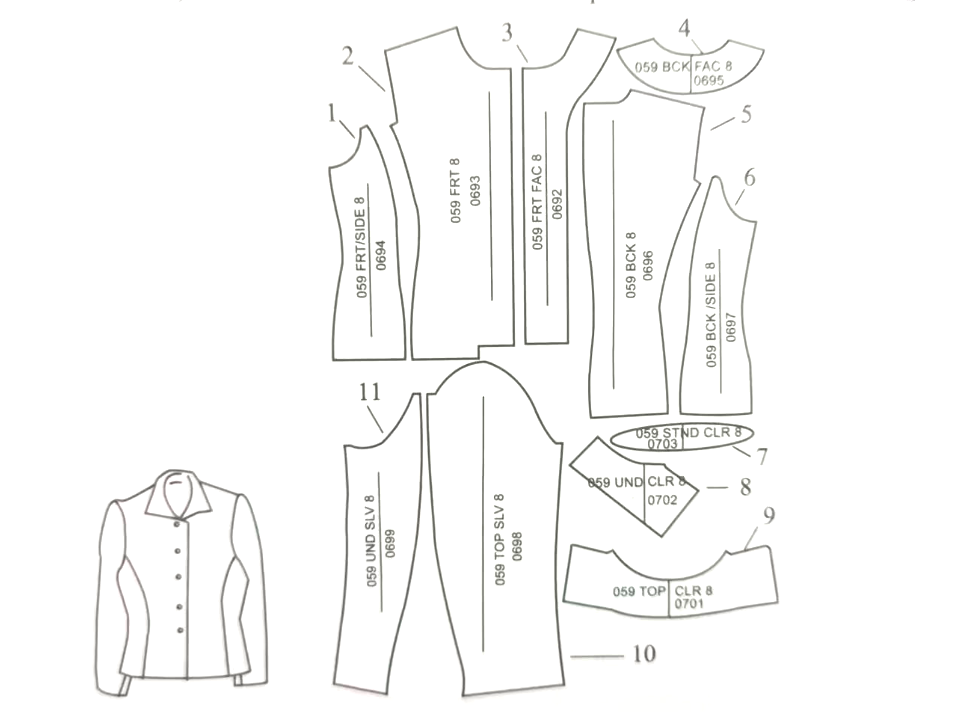

- STEP 2. Draw paper patterns

Drawing a paper pattern is the first step in making the renderings on the style drawing into a finished garment, which acts as a bridge. In production, drawing paper patterns is a key technical work, which is not only related to whether clothing products can faithfully reflect the requirements and intentions of designers, but also has a great impact on the process method of clothing processing. At present, the paper pattern drawing methods mainly include the prototype method, proportional distribution method, three-dimensional cutting method, etc.

- STEP 3. Trial production of sample clothes

After the paper sample is drawn, it is necessary to make a sample to check whether the clothing design and paper pattern design meet the requirements and whether the customer who ordered is satisfied. If the requirements are not met, an analysis should be carried out. If it's a matter of design, redesign the style. If there is a defect with the paper pattern, the paper pattern needs to be modified until the finished sample meets the requirements.

- STEP 4. Draw a production template

Based on the confirmed sample paper pattern the corresponding model specification series table and other technical documents, we draw the base type template and introduce the required number model template.

Athletic Wear Wholesale Vendors pushes the plate according to the model specification series table on the basis of the customer's national size chart and finally obtains the production series samples of each specification required in the production task list for cutting, cutting and process development.

- STEP 5. Develop the process

According to the requirements of clothing styles or orders, according to the national standards of clothing products, and the company's own production status, the technical department of Athletic Apparel Vendors will determine the production process requirements and process standards of the product, the technical requirements of key parts, the selection of auxiliary materials, etc. In addition, the technical department should also formulate relevant technical documents such as the sewing process to ensure orderly production.

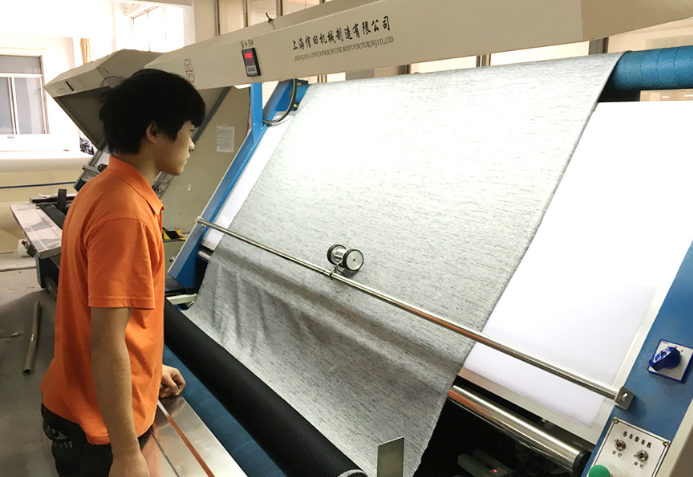

- STEP 6. Cloth inspection and pre-shrinkage

After the fabric enters the factory, it must go through the fabric inspection process, which is the basic guarantee of the quality of the finished garment. If the tested fabric shrinks and deforms greatly, it also needs to be pre-shrinked to avoid large differences between the specifications and dimensions of Private Label Yoga Wear and the calibrated specifications.

- STEP 7. Development of a cropping scheme

Also known as "split bed". When formulating the cutting plan, we first decide that a certain batch of production tasks need to be completed in several cutting beds, each cutting bed lays several layers of fabric, each layer of fabric is lined up with several specifications, and each specification is arranged several pieces, so as not to cause unnecessary waste.

- STEP 8. Nesting

Nesting is to scientifically arrange all the pieces on the cutting bed according to the determined cutting plan while maximizing the utilization rate of the fabric, it is also necessary to consider the processing factors such as the difficulty of cutting.

for next 4 steps, check Wholesale Blog (fit-fever.com) to know more.